First Time Right

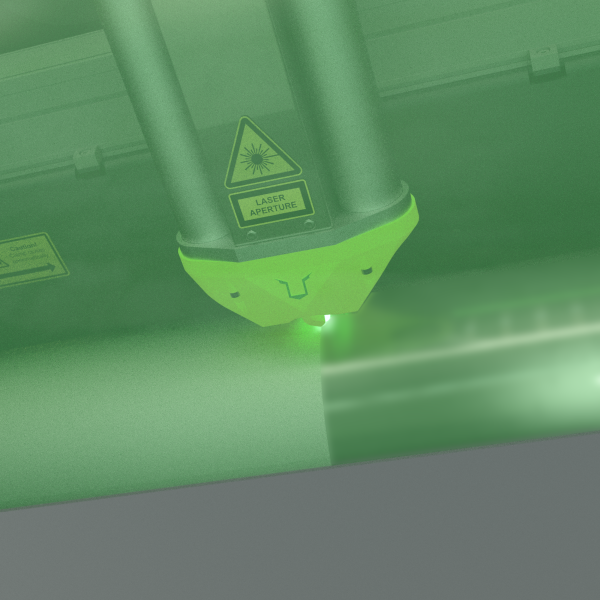

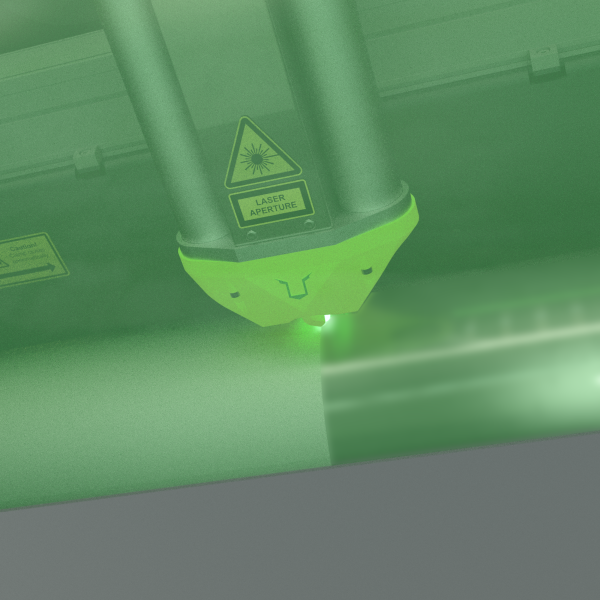

Can you believe it is possible to get the colors directly right over 80% of the times you set a new product on your flexographic printer? Our laser cleaning process is one of the key components in that goal!

First Time Right

Can you believe it is possible to get the colors directly right over 80% of the times you set a new product on your flexographic printer? Our laser cleaning process is one of the key components in that goal!

A combination of precise ink formulation and regular laser cleaning transforms the printing process from an “art” to a “science,” making it possible to achieve perfect results on the first run. This approach significantly reduces setup time, saving both ink and meters of print material. Additionally, it frees up more profitable hours for your press, maximizing operational efficiency and amplifying overall benefits.

At Lion Lasers, we pride ourselves on being at the forefront of Anilox laser technology, engineered to clean Anilox rolls and sleeves with unmatched precision, reliability, and without compromising quality. Our advanced technology is the culmination of extensive research and years of meticulous development, enabling us to consistently deliver superior results in both precision and durability. Our anilox laser cleaning fits into a First Time Right approach, that transforms cleaning from an art to a science, eliminating the need for repeated adjustments and ensuring an ideal outcome on the first run.

This approach saves countless hours of setup, reduces ink and material usage, and frees up more productive hours for your press, maximizing operational efficiency. Supported by our advanced technology and robust process design, We consistently maintain the integrity of Anilox rolls and sleeves—even after more than 250 individual cleanings on a single sleeve, without any degradation. This exceptional durability speaks to the reliability of our approach, which has been affirmed by independent evaluations and the positive experiences of our customers.

The First Time Right principle further emphasizes the accuracy and consistency of each cleaning, ensuring that even high line-count sleeves remain free from contamination within a 5% volume threshold, resulting in stable ink transfer and predictable print quality. That said, please note that reproducible ink recipes and consistent color matching by spectroscopic measuring is one of the other ingredients needed to reach First Time Right.

Our systems are meticulously designed to deliver safe, precise cleaning while preserving the quality of Anilox rolls and sleeves, and we take every precaution to uphold the highest standards in each cleaning cycle. Though certain external factors, like improper use or incorrect handling, may occasionally impact results, our technology is specifically engineered to prevent such issues as much as possible. We proactively work to minimize these risks by educating our customers on best practices, ensuring that your equipment remains in excellent condition.

By extending the lifespan of Anilox rolls and sleeves and reducing the need for replacements, our technology contributes to a more sustainable printing process. This aligns with our commitment to supporting a circular economy, minimizing waste, and maximizing resource efficiency for our customers.

If you’re excited to learn more or would like additional information, please don’t hesitate to reach out via the form below. We look forward to connecting with you!

Call us

+31 (0)76 3690490