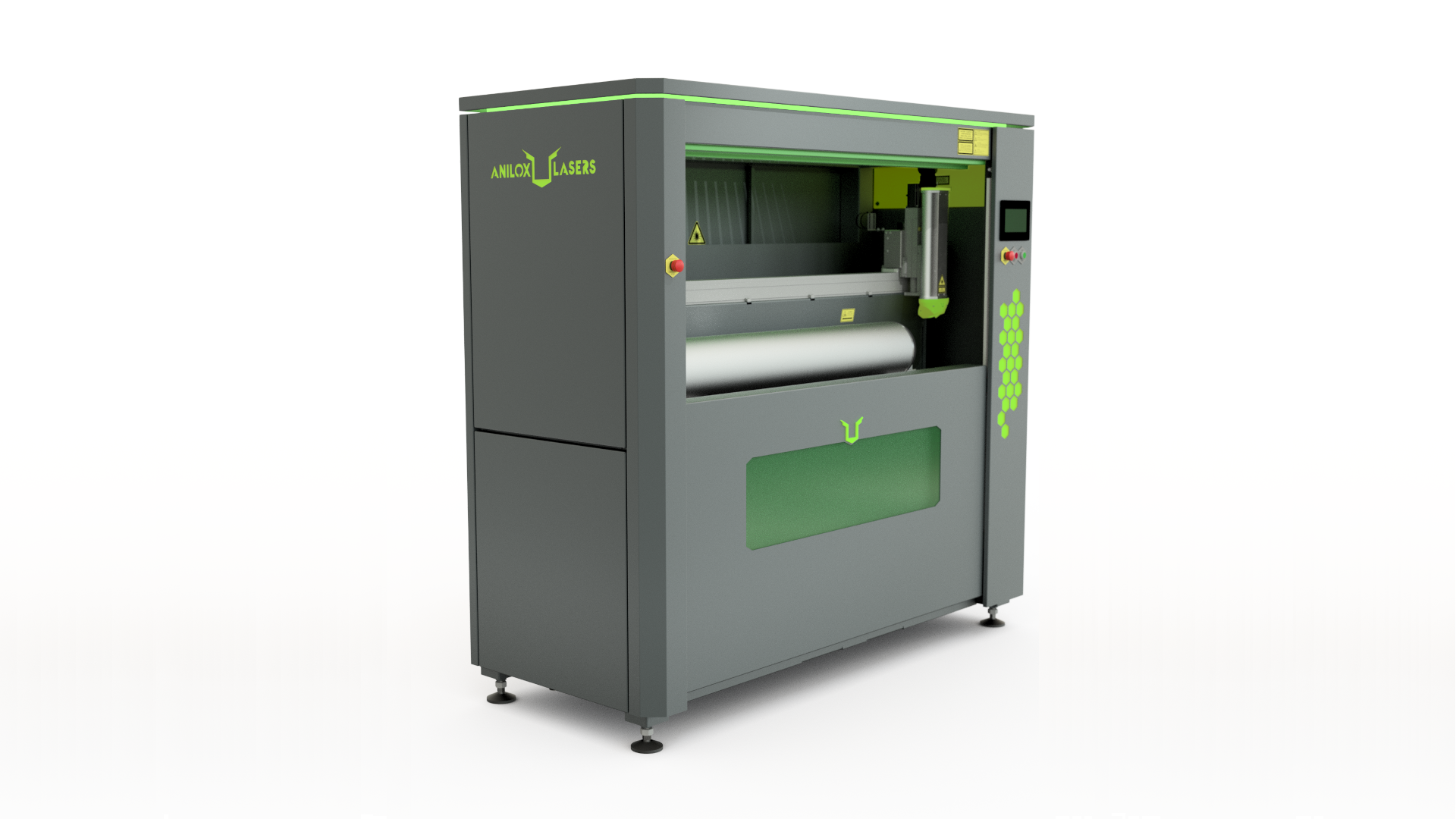

Meet the AL1600: a high-tech, fully automated laser cleaning machine for Anilox sleeves and rolls, capable of cleaning up to a maximum length of 1600 mm.

Description

The AL1600: Advanced Laser Cleaning for Anilox Rollers and Sleeves

The AL1600 is a cutting-edge, fully automated cleaning machine designed specifically for Anilox rollers and sleeves, utilizing state-of-the-art laser technology. Developed through close collaboration between industry-leading Anilox experts and the innovative R&D team at Lion Lasers, the AL1600 sets a new standard in precision cleaning.

Equipped with the latest XIR-MOPA laser techniques, this advanced system delivers highly controlled, accurate cleaning. Each laser pulse is meticulously calibrated to remove even the most stubborn polymer residues left by inks, ensuring a pristine surface without causing any damage to the delicate ceramic material of the sleeves/rolls. The AL1600’s automation capabilities ensure consistent, reliable cleaning results, significantly reducing downtime and extending the lifespan of your Anilox sleeves or rolls.

Whether you’re dealing with high lines anilox sleeves or rolls or particularly tough residues, the AL1600 provides a powerful, efficient solution that guarantees both cleanliness and protection, ensuring optimal performance in your printing process.

Our lasers never clamp your valuable rollers in metal chucks. We have designed a unique system that rotates the rollers in its own bearings. Thus preventing damage to your roll studs and making sure an easy roller change is made. For various rollers adapters are available or can be custom made.

Specifications

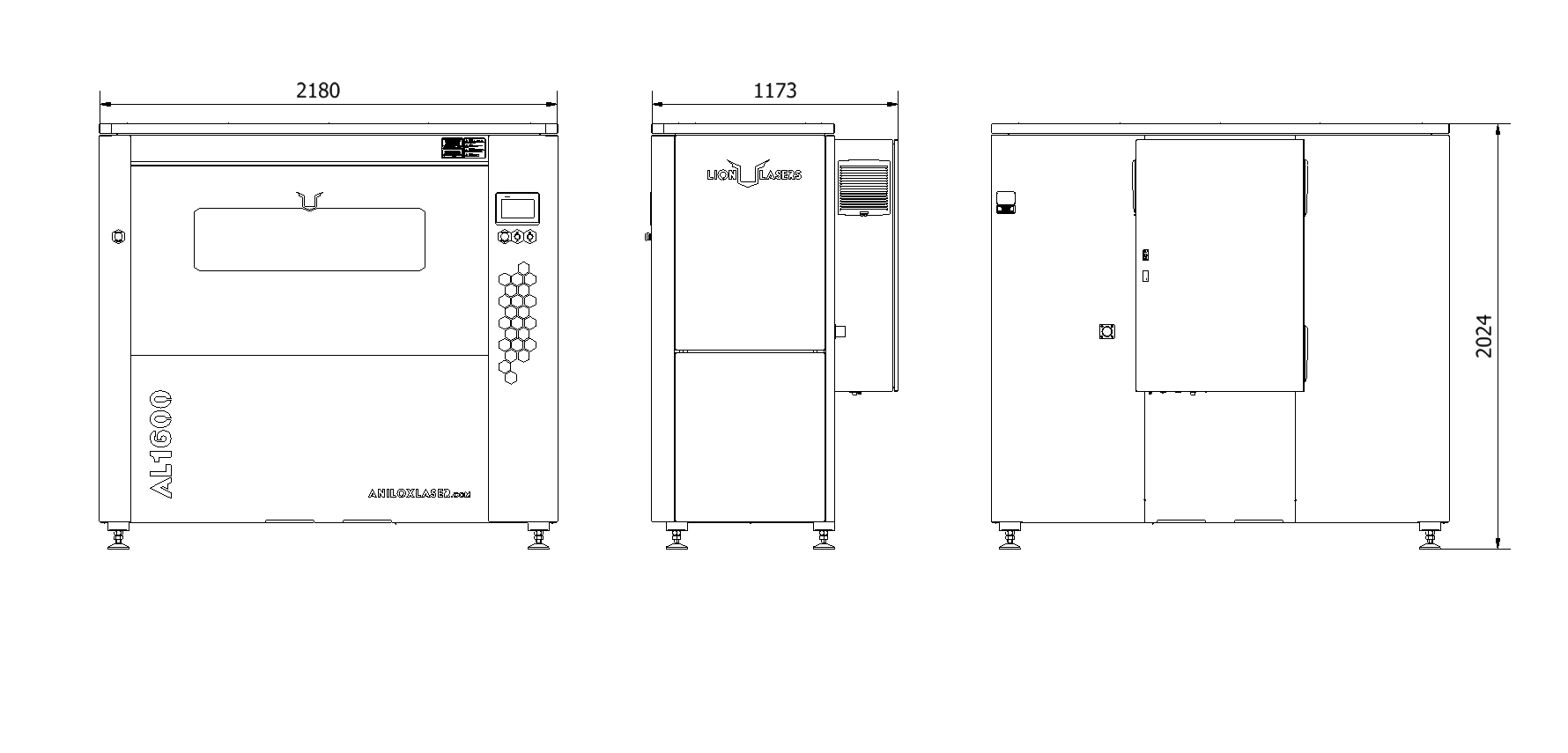

- Housing 2180 x 1173 x 2024 mm (W x D x H)

- Weight approx. 750 kg

- Workfield Anilox diameters: min Ø130 x 600 mm, max Ø205 x 1600 mm (other sizes on request)

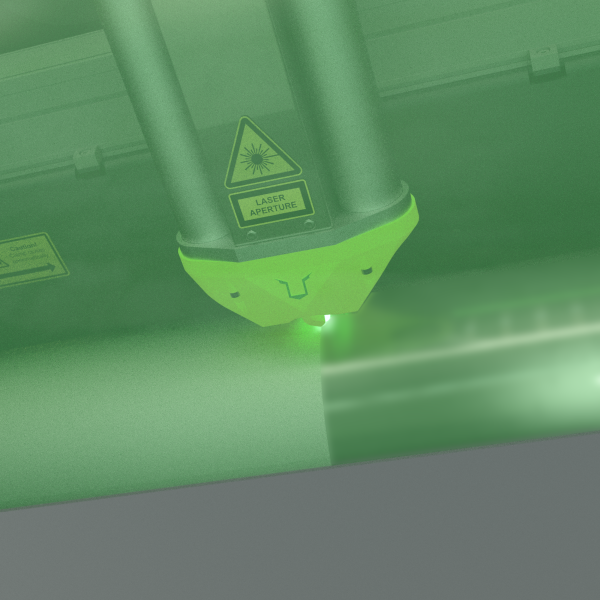

- Laserheid Lion automatic optical follow focus head

- Laser source XIR-MOPA (Master Oscillated, Power Amplified)

- Pulse length Optimized for efficient cleaning

- Pulse power Restricted below the damage threshold of ceramic anilox materials

- Pulse frequency Automatic pulse frequency adjustment

Key features of the AL1600 include:

- Fully Automated Cleaning: Designed to operate with minimal user intervention, ensuring consistent and reliable results with every cycle.

- XIR-MOPA Laser Technology: Utilizes advanced laser pulses for precise, controlled cleaning without damaging the ceramic surfaces.

- Tailored for High Line-Count: Capable of effectively cleaning the smallest cell structures of high line-count Anilox rollers and sleeves, maintaining peak performance.

- Eco-Friendly Solution: Operates without the need for chemicals, reducing environmental impact and lowering operating costs.

- Optimized Efficiency: Minimizes downtime and maximizes productivity, allowing for seamless integration into your production process.

- User-Friendly Interface: Designed for ease of use, with intuitive controls that simplify operation and maintenance.The AL1600 is ideal for printing companies looking to enhance their cleaning processes, ensuring optimal ink transfer and print quality, while protecting their valuable Anilox equipment.

More systems

Request information

Call us

+31 (0)76 581 0101