Because our laser cleaning does not damage the anilox, you are able to clean the anilox as many times as wanted. Read further below how our laser cleaning process works and why this benefits your printing process…

Process

Process description of Anilox laser cleaning

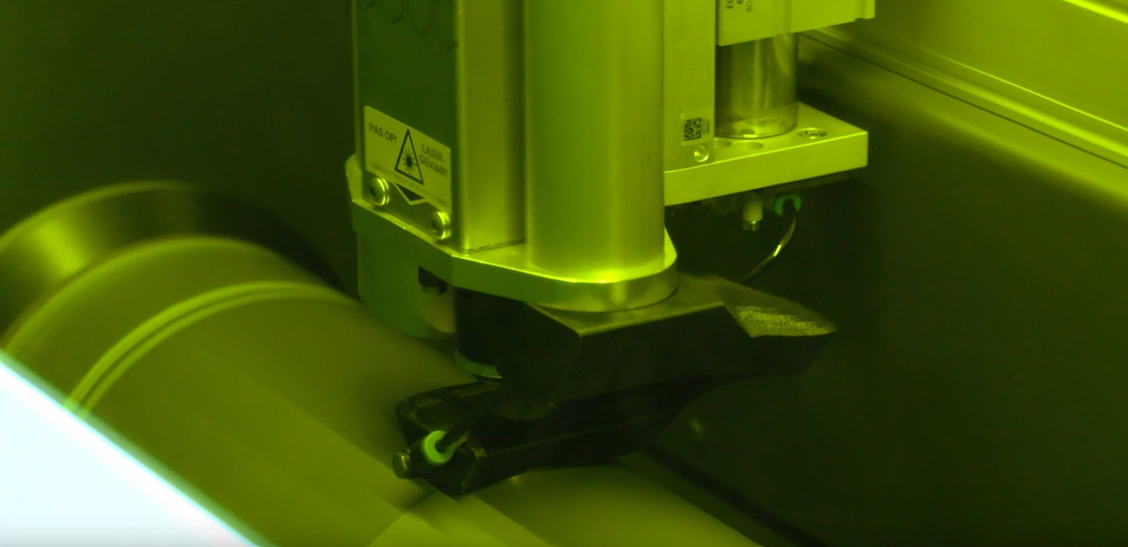

The development of Lion Lasers’ Anilox laser cleaning technology began with an extensive preliminary investigation, where we determined that contamination could be effectively separated from the ceramic layer of Anilox rolls and sleeves using a carefully calibrated laser technique. This foundational discovery highlighted critical differences in how contaminants and the Anilox base material respond to laser interaction, guiding our focused refinement.

Our goal was to remove stubborn polymers and inks entirely while preserving the intricate structure of the Anilox cells. This phase involved a long period of testing and fine-tuning, drawing on a variety of advanced technologies and high-quality materials to create a reliable and durable solution.

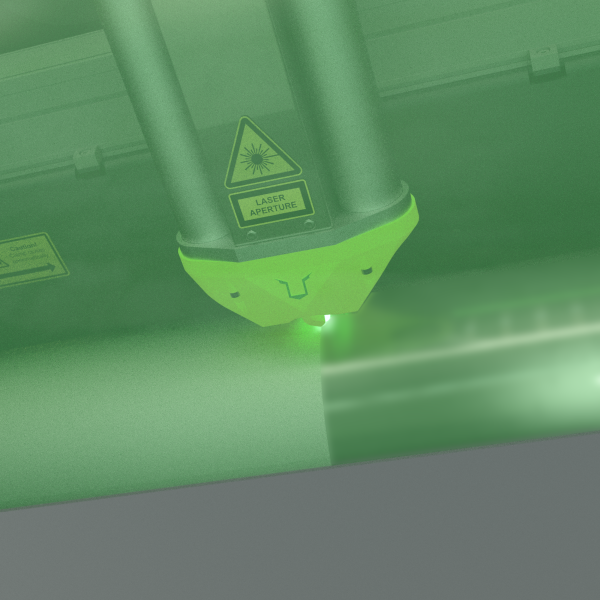

Conventional laser systems where not able to get the pulse-stability from first to last pulse in a sequence, needed to prevent micro cracks, so we had our laser source manufacturer made sources to our needs and we tuned them until we reached the desired result. Our XIR-MOPA laser source was born. Achieving the right balance in the system required to have all variables in hand. Out system is filled with sensors and control all settings to laser parameters, including pulse power and width, frequency, focus shaping and distance, rotation speed of the Anilox and much more.

Though the development process took longer than initially expected, it led to a major breakthrough. The resulting laser system operates with extreme precision, ensuring safe, thorough cleaning without risk of damage, even after hundreds of cycles on a single Anilox sleeve.

The outcome is an innovative, safe, and dependable laser cleaning technology, developed in collaboration with Anilox experts to meet the highest industry standards. The success of the system is confirmed by positive customer feedback, such as from Oerlemans, a valued member of the OPAC Group, who praised the AL1500 (a predecessor of our latest models) as the most effective and safest system available worldwide after extensive testing. This endorsement highlights our commitment to quality, precision, and sustainable solutions, underscoring the value our process brings to the printing industry.

With the Anilox laser Marinus van Kalkeren and co-workers from Oerlemans where able to maintain contamination levels consistently below 5% of volume, even for high liniature sleeves. This by laser cleaning each sleeve at least once a week. This approach ensures ink volume remains stable, transforming printing from an interpretative art to a predictable science. By achieving optimal results on the first pass, Oerlemans reduced setup time, substantial ink savings, minimized material waste, and reliable print quality, enhancing operational efficiency and product consistency.

Now Marinus is available to help you introducing the Anilox Laser in your printing process. You can contact him directly to discover how he can help you improving your process.

Anilox Cleaning Excellence: Game changing benefits,

- Unrivaled color strength: Maximize ink performance with consistently vibrant results.

- Precision in print: Achieve predictable, high-quality output every time.

- Efficiency redefined: Minimize press setup time and boost overall productivity.

- Ink savings: Reduce ink consumption while maintaining top-notch quality.

- Waste reduction: Lower material waste during setups, saving costs.

- Uninterrupted production: Cut down on press downtime and streamline operations.

- Chemical-free cleaning: Eliminate the need for harmful cleaning agents.

- Health and safety guaranteed: No workplace hazards linked to chemicals.

- Sustainable operations: Remove environmental concerns from chemical use.

- Superior print accuracy: Maintain tighter tolerances for color consistency.

- Customer satisfaction: Consistently deliver superior results for happier clients.

Contact

Call us

+31 (0)76 3690490